Kingspan Off Site made the move to Tekla Structures to assist in the design and engineering of its systems, which in turn directly drive its manufacturing process.

Kingspan Off-Site ± Profiles & Sections located in West Midlands is a subsidiary company of the Kingspan Group. The business has been providing steel manufacturing solutions to the UK and European markets for over 20 years. Kingspan Off-Site is firmly established as a manufacturer of light gauge frame construction systems and has recently grown into a high volume manufacturer in advanced modern methods of construction utilising high levels of on and off-site manufacture (OSM) technology.

Kingspan Off-Site has initiated a strategic project to implement 3D modelling capabilities and to integrate the design and manufacturing facilities within the company. Tharinda Rathnapala is a 3D modelling researcher for Kingspan Off-Site. Although his initial degree speciality is Automotive Engineering Design, he was recruited to help optimise the companyÝs design and production processes.

Tharinda has been with Kingspan Off-Site for 1.5 years ± about the same time the company started to use Tekla Structures. Kingspan Off-Site employs ten detailers, and currently holds a number of Tekla Structures licences. Tharinda explains the choice of Tekla Structures, ýTekla has the leading presence in the UK construction industry,¯ he says. ýThe market reputation and usage within a number of leading steel detailing companies around the world solidified Tekla Structures as our primary choice of 3D modelling software¯.

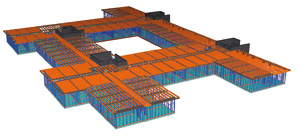

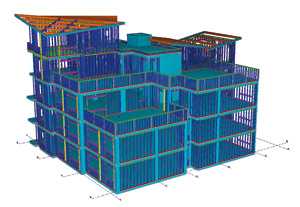

Kingspan made the move to Tekla Structures to assist in the design and engineering of its systems, which in turn directly drive its manufacturing process. Initial assessments have proven very positive in the use of Tekla Structures in complex live projects.

The latest 3D environment helps the designers to detect any possible issues within the given construction project and clarify those issues prior to site installation. The clear advantage is increased efficiency in the design phase, which ultimately results in minimised product cost and a shorter delivery period to customers. Kingspan Off-Site is able to receive 2D or 3D CAD information from a number of different CAD packages. This allows the Design Team to quickly assimilate 2D information from a third party in to an intuitive and intelligent 3D environment. This makes the review of geometric data faster, highlights possible conflicts earlier and means the 3D model is a thorough and complete set of information.

In addition, Kingspan Off-Site has developed total customisation of Tekla Structures software to provide its in-house design team with key function-driven tools to quicken the design process. The company anticipates further time reduction in planning and manufacturing procedures due to specialised CNC coding.

The companyÝs Kenton Road project is a successful example of a load bearing project completed within a 3D environment. This residential development consisted of a two storey load bearing structure with a complicated duo-pitched roof above three storeys of infill framing.

Project Design Manager Peter Jones states, ýUsing a 3D environment was useful to solve issues with complex light gauge steel roof structures within the project. Tekla Structures reduced the time required in processing drawings whilst maintaining our high standards. The parametric features available contributed heavily to bring the project design stage to conclusion in a record time.¯

Technical Design Manager David Yates adds, ýHaving the ability to investigate the model in a 3D environment was a key element to solve onsite issues and design complications raised during the project, helping remove the project design stage from the critical path.¯

Interoperability

One of the most significant innovations in Tekla Structures is the open application programming interface (Open API), which makes it possible to tie together the different design applications and disciplines into a common 3D product building information model.

Open API facilitates the integration of different design applications, such as analysis and design software into the modelling environment. The Open API also makes it possible to develop additional functionality into the Tekla Structures platform. The Tekla Structures Open API is implemented using Microsoft .NET technology.

Kingspan Off-Site currently uses the .NET API to retrieve information from a given model. The system without doubt provides more benefits for the Kingspan Off-Site design and manufacturing process. The company has also looked into using the Tekla web publishing facility to provide 3D information to clients and sees this function as a positive impact on service in the future.

Tekla support

Kingspan Off-Site has found the customer service and technical help extremely approachable. Tekla is committed to customer support and helps all new users get started as well as maintain development. Tekla also heavily invests in R&D. This means that each new software version makes a substantial difference in day-to-day productivity, allowing the user to focus on design while managing other valuable assets: data and information.

With regards to future technical developments, Tharinda states that ýtraining is a key aspect to implementation. As Kingspan Off-Site begins to get more experienced Tekla Structures users, the number of licences will in turn increase.¯ He continues, ýWe intend to roll-out all projects in the future with Tekla Structures. This means we will use Tekla Structures for all sectors equally. At the end of the day, this not only creates a more efficient process for our other services but also maximises our level of ability to serve our customers more effectively. Overall, a winning situation.¯

www.kingspanoffsite.com

www.tekla.com