One year on from his appointment as managing director at Allplan, Richard Brotherton speaks to AEC Magazine on how AEC technology is evolving and the company’s plans for the future

Q: Historically, Allplan has been strong in Germany, with its BIM products for architecture, engineering and facilities management, but less well-known in the UK. You have. How do your customers break down by sector?

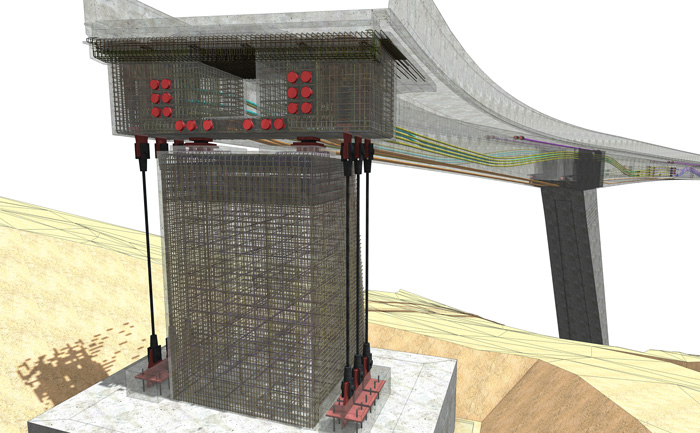

A: Allplan benefits from offering one platform for architecture, structural and civil engineering and, while different users will naturally work with different aspects of that platform, it provides a single environment for all users. In particular, we believe we offer a unique workflow that combines 2D and 3D processes without compromising the quality of drawings. This, in addition to our comprehensive solution for rebar detailing, makes Allplan a compelling solution in the engineering market, with over 250,000 users across the disciplines. Our products are being used on everything from the world’s longest three-tower, cable-stayed bridge, the Queensferry Crossing in Scotland, to the world’s longest tunnel, the Gothard Base Tunnel in Switzerland, as well as many landmark buildings such as the Sky Tower in Germany.

Q: In the early days of BIM, Allplan stood out for its focus on cost management. How has this influenced product development over the years?

A: Cost management has always been central to Allplan’s offering in countries like Germany, but in reality, costing processes are very region, which makes this workflow difficult to bring to other countries. However, it’s still very much at the heart of our thinking and we fully support initiatives to integrate costing solutions with Allplan. As an example, we work very closely with our sister company Nevaris [also part of Nemetschek], and with our cloud CDE [common data environment] solution Allplan Bimplus. This way, we’re able to link to specific solutions our clients require.

Q: In 2017, Allplan opened a new UK office – why the UK and why now?

A: The UK has been at the forefront of BIM processes and digital construction for many years and is supported through the UK government’s BIM initiatives. As a result, we see the UK market as a key player on the international BIM stage. I believe BIM is on the verge of transforming the industry and, with Allplan’s software solutions, we believe we can help the industry achieve its goal of Level 3 BIM.

Q: In the UK, we have some very specific industry initiatives to make BIM a country-wide standard. What developments and capabilities has Allplan included in the software to assist customers to meet standards such as the UK version of COBie, for example, and achieve interoperability? And how does this compare with what you see globally?

A: The goal of delivering Level 3 BIM is to provide complete traceability of every object, in order to support the entire lifecycle of the project. This is something Allplan has been able to do for many years. The properties of individual drawing elements and objects can be tracked through the entire design and delivery process. In addition, Allplan is intrinsically linked to our CDE and collaboration tool Allplan Bimplus, an open platform for managing models and all associated project data with the entire project team. We also support export of BIM data via IFC4 and the open BIM approach for maximum interoperability.

Q: Many new members of the Allplan team, yourself included, have a background in structural engineering and fabrication (at Tekla, CSC and AceCad). Should we read anything into this, in terms of the direction in which you intend to take Allplan?

A: No – this domain knowledge just helps to ensure we continue to provide the right solutions for our clients. We, of course, have sister companies such as SDS/2 for steel fabrication and PRECAST for concrete fabrication that work together with Allplan to ensure a comprehensive solution for structural engineering. Again, these are managed seamlessly through our cloud-based CDE platform Allplan Bimplus to ensure users can use best-of-breed tools without compromise, enabling an effective workflow.

Q: Software developers have been very keen to jump on the cloud bandwagon and, at AEC Magazine, we can see how this helps collaboration, but we also see hurdles that must still be overcome. How does Allplan handle group working and distributed team collaboration – and how else do you use the cloud?

A: We’ve developed Allplan Share, a cloud-based collaboration tool that supports multi-user working, even when users are in different locations. Based on Allplan Bimplus, it opens up flexibility in your project teams and removes the obstacles associated with working virtually in the same location.

Q: Coming from the Nemetschek stable of building design products, which also includes well-known brands such as Graphisoft ArchiCAD, Vectorworks and MAXON Cinema4D, how does Allplan differentiate itself from its stablemates – particularly those that offer BIM tools such as Vectorworks and ArchiCAD? And how is the group integrating and cross-pollinating technologies from its different brands?

A: As part of Nemetschek, we are in a unique situation, as some of our offerings might be seen to compete with those of our sister companies. However, we see this competition as healthy and something that drives our technology forward. It also provides customers with choice, enabling them to choose the right tool for the right job. More often than not, we actually complement our sister companies and our combined technologies provide customers with enhanced workflows. An example of this is the work we’ve done on data exchange with SCIA Engineer, whereby a direct connection simplifies interactions between modellers and engineers considerably. This is recognised in the group as a whole, and we have a number of cross-brand initiatives underway to bring enhanced workflow to our clients on platforms such as Allplan Bimplus.

Q: Architects, in particular, seem to be broadening their tool palettes by mixing numerous products together in the realisation of their designs. What kind of capabilities does Allplan offer for collaborative open BIM working and how do you see this changing in the future?

A: Allplan Bimplus supports a CDE across both open standard formats, such as IFC and so on, and closed BIM methodologies – for example, different API and SDKs. This means that numerous applications can be utilised via this cloud technology across many stakeholders, disciplines and applications, be it for architecture, engineering, costing tools or newer technologies such as HoloLens.

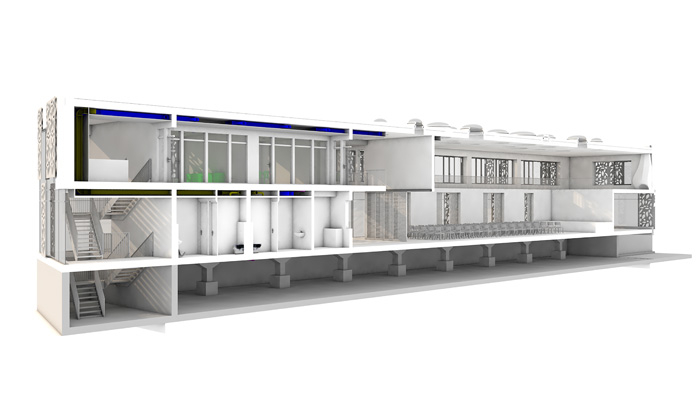

Q: Many users would agree that, when creating BIM models, automated 2D output can leave a lot to be desired. That can lead to a lot of reworking to get 2D output into the state in which customers would want to see it. Some users break up the process and take their drawings into AutoCAD, which means they lose the benefits of quick changes driving new drawings. Allplan has extensive documentation editing tools; do customers accept the default option, or is document-editing of sections and elevations still a significant part of the process?

A: I believe Allplan is in a unique position: its extensive 2D drawing functionality has been in the market for many years and combined with the requirements of 3D modelling. Therefore, we don’t have to compromise on drawing quality or the 3D modelling as a number of our competitors do. We can actually work predominantly in 2D and still derive the 3D BIM model. Some applications are mainly layout tools and not created to generate deliverables for detailed reinforcement, hence the user is required to manually create 2D deliverables or use alternative systems, thus breaking BIM workflows and introducing potential errors. With Allplan, the solution is not just about creating the layout but also using familiar working methods in the 2D/3D environment to detail reinforcement, thus delivering full manufacturing data and quality production information. Even better, with Allplan, users can detail almost any shape imaginable using a wide range of bar bending codes, including BS8666.

Q: We’re seeing a current trend in which users are using CDEs to ‘data wrangle’ proprietary data into a single, synchronised environment. What are your feelings on this?

A:Engineers and architects need flexibility; they also need to deliver constructible data, which often will involve numerous software solutions to ensure that no compromise is made on the quality of the project data. Also, it is simply more efficient to use the correct tool! We therefore believe that we need to be flexible and be able to communicate with many native and open file sources. It’s the philosophy behind Allplan Bimplus to be completely open to other solutions that our clients need.

Q: Model sizes are a common problem in BIM projects, with models growing as more detail is added. What’s a typical file size for a customer project for Allplan? What kind of RAM would a typical user require and does Allplan have methodologies for breaking up models into smaller work packages?

A: Our recommended RAM requirement for a standard PC is at least 16GB. Graphic cards are also important if you wish to take advantage of 4K resolution, which is new for Allplan 2018. An overall model can be broken down into a series of structured sub models, thus enabling users to only work on the sub models they need to, even in a multi-user environment. This makes the workflow quicker, more efficient and more manageable and we believe keeps file sizes comparatively low. In reality, therefore file size does not tend to be an issue.

Q: ArchiCAD has a live connection to Grasshopper. Does Allplan have any similar capabilities/workflows for computational geometry?

A: Allplan supports computational design with the import of the resultant model from the Grasshopper script.

Q: Could you give us some details on how Allplan supports parametrics?

A: Allplan is a full parametric solid modelling solution. We also have enhanced parametric intelligent objects controlled by Python called Pythonparts. An intelligent Pythonparts editor interface enables users to create their very own parametric objects and combine basic elements from pre-defined building objects – including columns, beams, foundations and stairs, for example – to create individual assemblies. In this way, recurring tasks are completed in far less time.

Q: It’s no secret that learning a BIM process can be a massive undertaking and thus a barrier to adoption for some potential users. What strategies does Allplan use in order to speed up training and keep the product from becoming excessively complicated?

A: Training is a vital element when implementing a solution such as Allplan. To maximise return on investment, training is always advised. We have a dedicated training centre in all our offices, in addition to telephone/email support from technical services and online self-help forums. All these resources help clients get up to speed as quickly as possible. We also have dedicated BIM consultants who offer both BIM consultancy courses and certification as well as BIM templates to companies and public-sector bodies. We publish an annual BIM Compendium [www.tinyurl.com/BIMComp] and invest significantly in BIM-related research at universities including the Technical University of Munich (TUM), the Leonhard Obermeyer Centre (LOC). Finally, we are of course the founders of OPEN BIM.

Q: With an increasing focus on digital fabrication in AEC, what’s Allplan’s vision in this area?

A: This is an exciting area as we see more and more technology enter the market from robots, 3D printing, even electronic bricklayers! It’s our vision to interface with such solutions, so that the BIM data created by an engineer is fully utilised downstream. We have invested in numerous projects around Machine Learning and Artificial Intelligence, which we hope to be bringing to market in the coming years.

Q: Finally, looking to the future, what technologies and processes do you think will drive adoption and improve the benefits already delivered by BIM?

A: First, we need to listen to our customers’ requirements and help them make the transition to BIM as easily as possible. This means ensuring we help them digitise core deliverables such as drawings, while introducing new workflows to support BIM adoption. And there is no doubt that cloud-based technology has its place and will continue to drive digital processes, with open collaborative platforms such as Allplan Bimplus.

If you enjoyed this article, subscribe to AEC Magazine for FREE